DOMESTIC POWER IN INDUSTRIAL AUTOMATION: NEXT-GENERATION PLC SOLUTIONS FROM GMT

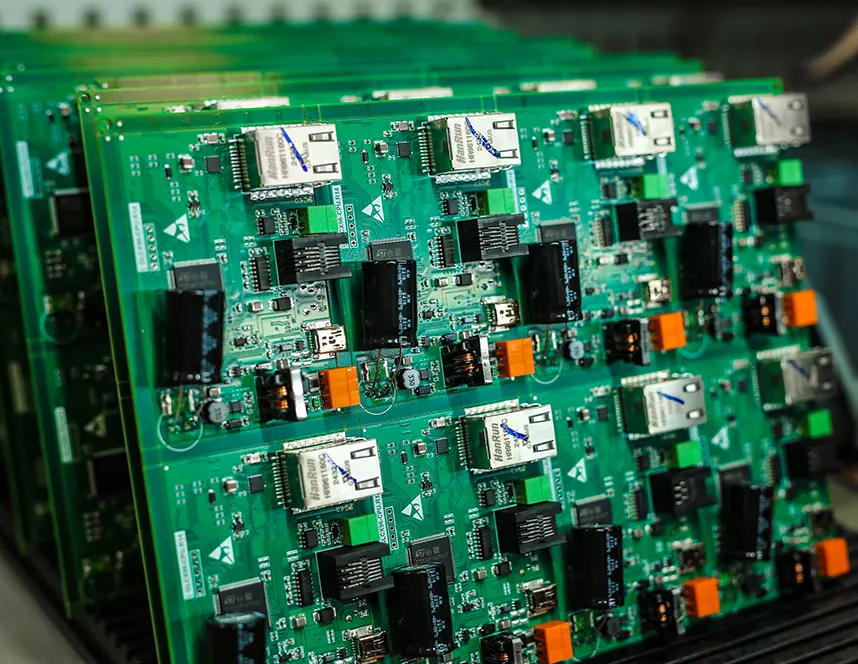

Representing Turkey’s domestic production power in the field of industrial automation, GMT continues to offer innovative and high-value-added solutions for factory automation, machine manufacturing, and Industry 4.0 processes with its developed PLC systems. Developed with a 100% domestic engineering and production approach, the GMTCNT PLC product group plays a vital role in the digital transformation journey of the industry.

Preferred in many different industrial applications as well as the machine manufacturing sector, GMT PLCs stand out with advanced technologies offered in critical processes such as data acquisition, remote monitoring, control, and reporting. With products developed in line with the Industry 4.0 vision, GMT both supports domestic production and aims to increase global competitiveness.

Remote Access Beyond Borders with WMI Technology

The GLC-396 and GLC-496 series CPUs, produced entirely domestically by GMT, make a difference in the sector thanks to their WMI (Web Machine Interface) feature. With this technology, users can securely provide remote access to GMTCNT PLCs from anywhere in the world with an internet connection, without the need for any port forwarding.

This feature offers great convenience in after-sales services, especially for machine manufacturers and maintenance teams. Companies using the GLC-396 and GLC-496 series CPUs can perform program uploads, downloads, monitoring, and intervention processes quickly and without additional costs, without being physically present at the machine.

Strong Infrastructure Compatible with Industry 4.0

The GLC-396 and GLC-496 series CPUs provide high performance in data acquisition and communication applications thanks to their MODBUS TCP Master / Slave support. GMTScada and GMTPort solutions developed by GMT offer a flexible and scalable infrastructure for monitoring, analyzing, and reporting production data. This integrated structure carries GMT one step ahead of its competitors in its segment.

Wide Application Range, High Preference Rate

GMTCNT PLCs are widely used in many sectors, primarily in textiles, food, metal processing, plastics, chemicals, agriculture, and livestock. GMTCNT PLC solutions are preferred in the production of numerous machines such as packaging, wrapping, filling, carpet washing, yarn transferring, steam generators, mills, ovens, meat processing, dried fruits and nuts, dough processing, dairy machinery, pipe bending, machine tools, extruders, PVC processing, CNC, injection, printing, press, paint, marble, woodworking, vacuum machines, and treatment systems.

Domestic Production Advantage: Strong Stock and Rapid Support

GMT offers fast solutions to its customers’ needs with the flexibility provided by domestic production. In addition to PLCs and mini PLCs with displays, GMT provides end-to-end automation solutions with a wide product range consisting of operator panels, speed control devices (inverters), servo motors and drives, stepper motors and drives, isolated repeaters, power supplies, temperature control devices, and industrial communication products.

Continuing to grow with the support of the Turkish industry’s power, GMT continues its R&D investments and product development studies in line with its vision of “creating a world brand from Turkey.”

For more information about GMT’s innovative industrial automation solutions, visit www.gmtcontrol.com.